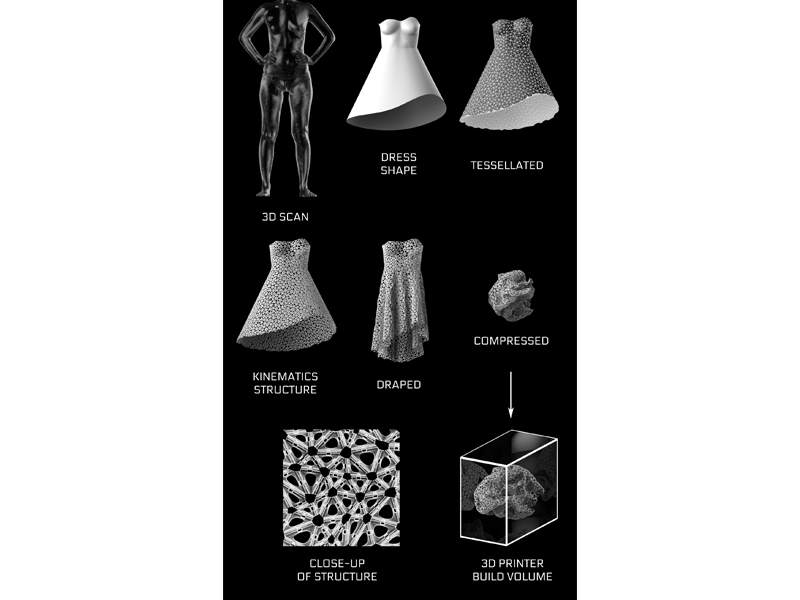

In May 2015, as part of extended research on contemporary jewelers’ use of new media, I had the good fortune of spending two hours with Jesse Louis-Rosenberg and Jessica Rosenkrantz, the duo who created Nervous System and brought digital cool to the little black dress. That project—a 3D-printed bit of fitted garment that has made its way into public collections—showcases their ability to push 3D modeling and printing softwares in ways that have made them a role model for much of their digitally minded contemporaries. That project, however, is just the tip of their iceberg. In this interview, they discuss how they got into programming and jewelry, why architects need to get with the program, and, most importantly, the fact that they are not really designing objects: They are growing algorithms.

Benjamin Lignel: Please describe in a few words your current professional status: What do you do, where, since when?

Jessica: I am an artist, designer, and programmer. The company that Jesse and I founded in 2007 is called Nervous System, and it specializes in experimental projects that combine art, science, and technology. My role is that of creative director, and Jesse acts as chief science officer. We are based in Somerville, Massachusetts.

Where did you train?

Jessica: I did my undergraduate studies at MIT, double-majoring in biology and architecture. While there, I worked in undergraduate research at the MIT Media Lab between 2003 and 2005, in the Physical Language Workshop group with John Maeda, where I worked on Design by Numbers, a programming environment for artists and designers that put drawing at the forefront of coding. I then went on to study toward a Master’s of Architecture degree at Harvard’s graduate school of design, from which I dropped out.

Jesse: Normally, when you draw something on the computer, there is a lot of overhead before you can put pixels on the screen. Design by Numbers made it possible to draw a line easily. Remember that we are not talking about computer-aided design (CAD) here, but about programming.

So, why do this through code—which I assume is much more time-consuming—than through CAD?

Jesse: CAD is always conceived to emulate traditional, analog operations: “Drawing,” “building”… In the space of programming, there is a lot more you can achieve than mimicking these analog operations. A good example is Casey Reas, an artist and a professor at the University of California, Los Angeles. Reas specializes in the history of computation in art, and has been working on dynamic, generative software for many years. His work builds on the work of artists like Sol LeWitt, creating works by writing down a simple set of sentences that define the rules for drawing. He uses computation to turn these rules into beautifully complex images—something that traditional CAD simply does not allow—rather than using software as a technical shortcut for, say, drawing architectural plans. This, for us, is the next level of what computation can do.

What were your personal expectations, when you graduated, about your future practice and business model? What did you think your relationship to object-making would be?

Jessica: In 2007, Jesse and I had already collaborated for a year and a half. We’d made our first pieces, for which we received a lot of positive feedback. At that point, I realized that we could run an independent studio, and support ourselves without depending on a job in academia, or on grants. One of our main interests is to study how natural processes create form and pattern, and we saw the studio as an opportunity to combine study, research, and production—and in my case, to mesh biology and architecture, which is not something the job market or academia would have allowed me to do easily.

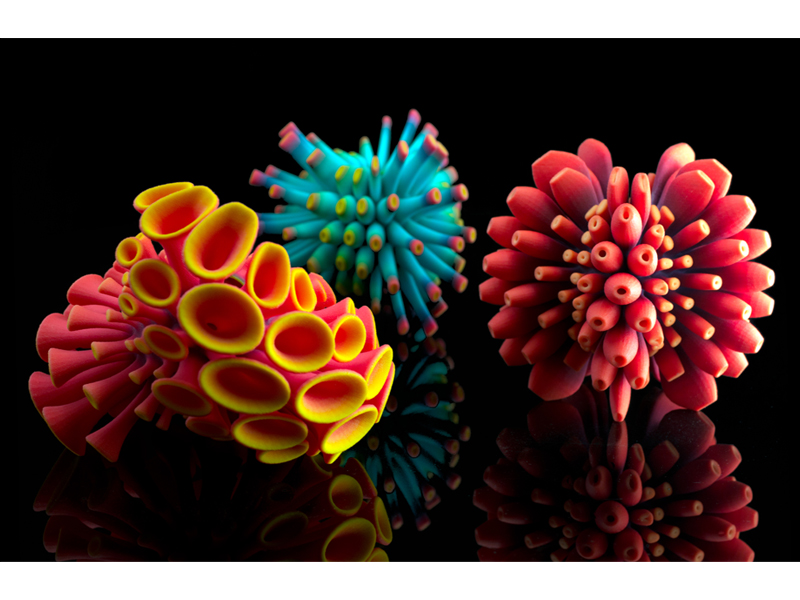

Jesse: I was training in math and computer science, and interested in what Jessica was doing. When the first Nervous System pendants—Dendrite—were produced, they confirmed that we could mash up our various interests and skills. Each Dendrite design is produced according to what is called a “diffusion-limited aggregation,” whereby two-dimensional “balls” are bounced in a virtual arena one after the other. Each ball randomly sticks to those already present in the arena, and those aggregates end up forming tendrils. We have produced more than 2,300 since they were first launched, and each of them is unique.

Jessica: It all started by accident, with this mock up…

Jesse: … are you sure you want to go that far back?

Jessica: Sure. (She produces what looks like a honeycomb structure sample in flexible, black silicone, not much bigger than the palm of her hand.) I was working on cellular meshes, as part of an exercise in architectural model-making, and had left this sample, folded, on my desk. Someone came in, and happened to ask if it was a model for a bracelet. Before that point, becoming a jeweler had never entered my mind, nor had the idea of opening a studio. The sample was indeed turned into a bracelet—that’s in 2006–2007—and was very well received. That’s what really made us see the potential in applying computation to object design.

Jesse: Computation was really controversial in design and architecture. In the MIT undergrad classes, for example, even using CAD software was strongly discouraged. And generating a design with code was even more questionable.

Can you explain why?

Jessica: A lot of the faculty had never used these tools. They did not understand how they worked, and were reluctant to see their potential. Computation undermined their own knowledge, which was invested in traditional methods of diagramming, drawing, and model making. When I presented designs to the class, I was invariably critiqued on my decision to use generative design systems, never on the project itself.

Neither of us learned CAD, by the way, but we both did learn programming.

Jesse: I taught myself…

Jessica: … and I took classes at MIT.

How does your training compare to other designers who use digital design in their work?

Jesse: Around the time Nervous System was created, I started working for Gehry Technologies. Frank Gehry’s relation to the digital design process is symptomatic of the field’s attitude. He is famous for pioneering cutting-edge, complex digital modeling, but his method is completely traditional: He develops his designs with scale models, made out of bits of paper draped over hand-fabricated structures. Computation was certainly not part of the design process. I would be called after a design was basically done and be asked to use computation to help figure out how to build it.

Does that have to do with inertia of thinking habits?

Jessica: Not only. There exists no good design software to design such a thing as a building anyway—a tool that would combine knowledge of materials, of building processes and constraints, and be design-friendly. That’s a first barrier. The other one is that to use computational tools effectively, you need to know them intimately, and that takes time.

Do you think that there might be a resistance, on the part of a starchitect like Gehry, to channel his creative abilities through programming? Doesn’t generative computation make it more difficult to assert authorship over a design?

Jesse: The authorship argument simply does not stand. “Authorship” stands in for “expressivity.” Gehry knows how to express himself very well through the use of paper models, and he does not know how to use programming. This question crops up all the time in interviews, and the answer is simple: If you master computation, you can express yourself through it.

Would you describe new technologies as processes (in the same way that casting is a process), or as a medium (in the way that oil painting used to be described as a medium)?

Jessica: For us, 3D printing is just a process; our medium is algorithms.

I would describe our practice as a kind of digital gardening. Instead of cultivating plants, we’re cultivating algorithms. We ultimately want to create systems that have their own innate behaviors which we can sculpt and manipulate. As we’re developing the software, we code sets of influencers, gradients, and manipulators that enable us to sculpt the growth. We’re fascinated by the interplay of what the system does innately and our manipulations.

What has guided your choice of output, which includes jewelry, household objects, and puzzles?

Jessica: Our choice has been largely practical: We focus on things that we can afford to design and produce on our own, and on things that we like.

Would you say that digital fabrication lends itself to cross-disciplinarity?

Jesse: Basically, yes. Digital fabrication has spurred a lot of development in open-source, collaborative ventures. The nature of the language we use—which is essentially mathematical, and allows no room for misinterpretation—means that disparate people with different backgrounds (and often living far apart from one another) can easily work on the same project at the same time. Traditional techniques, by contrast, have a higher access barrier, and are sequential: Someone fabricates this, then someone else adds to it, etc.

Jessica: Digital fabrication provides low-barrier production methods. The way people share information is more fluid. 3D printers are easier to use than traditional ways of making precision parts like injection molding or machining. 3D printing is also a very young technique, still mostly unexplored: It is open to exploration in many different directions. We don’t really know what it is good for yet. What industries should use it? What materials can it fabricate? There are so many potential directions of exploration that span disciplines from material engineering, medicine, manufacturing, and art.

Jesse: This “exploratory” spirit is shared by designers and manufacturers. There is no institutional inertia. Things work differently amongst more traditional manufacturers: It took a long while to find anyone who would accept to photochemically etch our one-off Dendrites.

Is it for you a question of designing generative systems and then looking for potential applications?

Jessica: Sometimes we will work on a generative system for a while before we find any specific applications for it. And sometimes we have a specific application in mind and then develop a generative process for it.

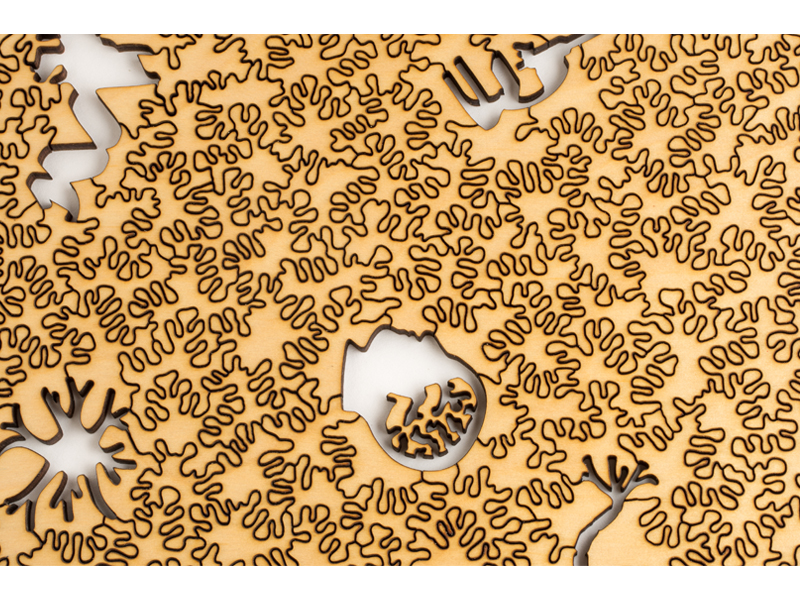

Jesse: Our jigsaw puzzles are a good example. Like many people, we grew up doing jigsaw puzzles, but only recently did we learn about the original tradition of cutting jigsaw puzzles by hand, using a scroll saw. The pieces in those puzzles are more diverse, beautiful, and interesting than in an industrial, die-punched puzzle. They can be more tricky, as they sometimes respond to, and play around, the lines of the puzzle’s image. That tradition, however, is all but extinct. There are die-hard fans, but these are rare.

So we decided we wanted to combine this old technique with new technology. We created a computational system inspired by a pattern based on an ancient ammonite fossil. (Jessica brings to the table an example of the fossil. Its glossy surface is striated at regular intervals by very fine squiggly patterns that look a lot like Nervous System products: systematic and singular.) The cut-designing system that we have emulates these lines, and like our Dendrites as well as traditional hand-cut puzzles, every one of the puzzles we produce is unique. We wanted to revive the spirit of 19th-century puzzles, but using 21st-century technology and techniques.

3D printing was heralded as a revolution, and some recent articles continue to describe it as a new dawn for home-based production. (Print spare parts for your Hoover at home!) Other (possibly more realistic) reports underline just how hard it is to get a sense of the possibilities of 3D prototyping and fabrication. Which of those claims make sense to you?

Jessica: It is not unreasonable to think that people could be printing at home, or at the corner shop. We actually do print spare parts for our apartment. The real hold-up is not the printing technology but the design software, and people’s proficiency with it—this is much more of an impediment than the actual printing.

We published an article on Art Jewelry Forum which made the contentious assertion that 3D-printed objects were limited by a self-similar 3D-printed aesthetics: molecular, fractal, proliferating. Rather than trying to stay away from these forms, you have embraced them and continue to develop them. Do you think that digital fabrication has a sort of aesthetical “ceiling”? Is this question missing the point of what innovation is about for you?

Jessica: As we said, 3D printing is just a manufacturing tool. There are essentially no limits to the types of shapes you can make with the technology. The only constraints one currently has are that (1) the model you are making will print in only one material, and (2) your structure must be monocoque.

We—personally—are interested in generative systems. To be specific, we are interested in how forms can be generated; how they are translated into physical objects is secondary.

Jesse: Many 3D-printed objects are single-material, and single-process, so they do have an identifiable “look.” Unless they are post-processed (painted, sanded, etc.), they certainly will look 3D printed. Traditional making processes, in contrast, are more layered, and sequential. But imagine, for example, if you set out to make an object using only a drill: It would look like it was made with a drill.

I am wondering if the technology of 3D printing is not convergent toward certain forms—a bit like the twisted tendrils and curlicues of ironwork.

Jesse: Not really, but in the very short history of the artistic usage of 3D printing, the recurrence of certain forms (such as wireframes and cellular structures) has to do with the fact that these sorts of structures were extremely difficult to make before. But 3D printing makes it quite easy to create these complex shapes. That makes them very compelling to explore. Also, they require a minimal amount of material, which is directly tied to the cost of producing them. These shapes, in turn, became popular quickly, and spurred demand.

In short, these recurring forms are challenging, cool, and cost-efficient. The combination of these three factors led to the rapid diffusion of complex 3D-printed wireframe structures.

You try very hard to make your proprietary tech available to the public: first, through the various apps that allow buyers to custom-design earrings, bracelets, or pendants; second, by making your source code public under creative commons licenses. I have two questions around this aspect of your work.

What percentage of your buyers custom-design a piece for themselves, using your apps? How would you describe their contribution: as a form of participation? Are they, to any extent, co-authors of the piece they “designed”?

Jessica: Around one-eighth of our retail sales are custom-designed pieces. We like to use the term “co-creation” to describe what these customers do. What comes out of their hands is a hybrid: it looks like what we do, but we would never do it the way they do it.

Jesse: Our apps are a little like coloring books. You (the user) can’t claim authorship, but you can feel (and express) pride about your drawing.

Jessica: We built the apps with two constraints in mind: that the co-creators could only design something that could then be produced physically, and that the apps would be easy to use by non-designers. All sorts of things have happened. Some people have wanted to use the apps to create work that they would sell as their own; more commonly, customers use the apps to tweak the size of the object. The people that really use the app’s design functionality do things that usually do not look like something I would make.

Do you disown those outcomes of your app?

Jessica: No, I claim partial ownership of them…

Jesse: We do not have a culture of making things (our relationship to “making things” is similar in some way to our relationship to math, and it gets the same sort of blanket treatment: “I don’t do math,” “I don’t make things”). We are trying to address that, and to trick people into having a bigger hand in making things for themselves. As people become more fluent with these apps, so will the potential of 3D modeling and printing unleash itself.

Ultimately, your practice is less about designing objects than it is about developing tools to generate those objects. How does one turn this into a business model, when the apps themselves are free?

Jesse: We make most of our money on the sale of jewelry, puzzles, and lamps. That money funds our experiments, which in turn feed back into our production. We spend our time, as designers, writing code, designing software … which we don’t sell. This model—where you don’t sell what you create, but a by-product of it—does not exist elsewhere. We don’t want to make a ton of money. We are really only interested in funding our work as researchers and artists.

This sounds strange to people who are in the startup culture: They expect growth, and a lot of windfall. Nervous System is not Facebook. We sell affordable products and write software.

On the website, you advertize “one-of-a-kind somethings for your one of a kind someone”: Although some of the techniques you use are meant for repeat production, you seem to constantly push digital fabrication in the direction of the custom-designed. As a result, your products and projects seem to always walk a tightrope between the “parametrically unique” and the repetitive. Are you interested in developing objects that are unique in the same way that a snowflake is unique?

Jessica: Yes, I am interested in developing objects that are unique in the same way snowflakes are. However, it’s not just about uniqueness itself but about creating designs with meaningful differences that are guided by user input. The dynamic processes we see in nature are capable of producing a plethora of unique forms. I’m interested in harnessing that span of design possibilities and making it something we can control and explore.

What does “pushing this technique to its limits” mean for you? What part of your involvement with digital design excites you most? What project that you are working on best encapsulates the possibilities of digital design?

Jesse: We like to do things that we have not done before.

Jessica: The promises that 3D printing holds are threefold: to make complexity free; to make customization free; and to lower the barrier to creation. We like all three, but we are not quite there yet. The Kinematic system, and the dress that came out of it, try to do all three at once—and it ends up at the limit of what we can do. As I said previously, the challenge has little to do with the printing technique. It has to do with the software: modeling the body, tessellating its surface, creating the hinges, growing the hinged, triangular cells, folding the dress so that it would fit in a small printing machine…

We have made four dresses so far: three for Autodesk (which is using them as showcase pieces), and one for MoMA. They are not yet for sale. They are far too expensive to my taste (they cost about $7,000). I am not interested in selling expensive objects: I want our one-offs to compete with mass-produced objects.

A link to Nervous System’s projects can be found here.

INDEX IMAGE: Jesse Louis-Rosenberg and Jessica Rosenkrantz, 2014, photo: Ash Adams