Since its inception in the mid-twentieth century, art jewelry has been defined by limited hand production in an artistic studio-practice paradigm. However, in the 1980s, advances in computer-aided design and manufacturing technologies led to the expansion of this definition, rendering the studio and hand manufacturing useful characterizations rather than steadfast criteria for defining art jewelry. Indeed, the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) technologies to create art jewelry has been a contested subject over the last 30 years, largely in academic circles. Today, the incorporation of technology in art jewelry seems a moot point, given the proliferation of art jewelers integrating these tools. Rebecca Strzelec, Phil Renato, Anthony Tammaro, Doug Bucci, Svenja John and Richard Nelipovich are but a few makers using technology to design and manufacture art jewelry. Even within AJF, computer-generated, laser-cut ‘coffee stain’ brooches by Arthur Hash are now offered to new and renewing members.

What we now refer to as Web 2.0 is essentially a set of easy to use tools – often online networks or platforms – that empower users to create and share digital content without having to know technical code language. As a primer, you might watch Michael Wesch’s 2007 video The Machine is Us/ing Us. Web 2.0 and the access it awarded to the average computer user has been pivotal in shaping the contemporary media landscape. Since the inception of Web 2.0 platforms in 1997, a drastic shift in the marketing and distribution of media content (i.e. music, print, television and film) has occurred. As barriers to content distribution have come crashing down and technology has improved, while also becoming more affordable, the monopoly media conglomerates held in the twentieth century has been eroded. And with this erosion went the supremacy of experts.

In 1990, to make a professional (or near professional) quality movie one would have needed costly film equipment, trained operators, access to post-production facilities and equipment, capital to cover printing costs and a distributing partner in order to effectively recoup capital expenditures as well as to actually share the product with an audience. This extremely costly process was the reason for the development of Hollywood movie studios. A consequence of this media creation and distribution model was the very high barrier to entry into the business, thus filmmaking was reserved for professionals and audiences were strictly film consumers. By 1999, home recording and editing technology had advanced significantly, allowing films like The Blair Witch Project to be made for $22,000 and to gross almost $250 million. It wasn’t until late 2004, however, that Web 2.0 video sharing platforms like Vimeo and YouTube launched and fundamentally changed the way video is distributed today. Once access to affordable video technology became widely available along with a free means for broad distribution, the entire culture of video creation was altered resulting in a cultural shift from passive video consumerism to active video producerism. This shift is evidenced by the equivalent of 150,000+ full-length feature movies that are uploaded to YouTube each week.

And though the example here is video and film, this same phenomenon, of producerism, holds true across all media content. Blogs and Twitter have changed the landscape of traditional print media, while the music industry is adjusting to a climate where ticket sales for live music are more profitable than record sales, largely because of digital music sharing. Because of our access and ability to freely share content, media production that was once reserved for only the media publishing industries is now in the hands of anyone with a computer.

To date, the creation and distribution tools that spurred Web 2.0 have been applicable only to digital media. The prognostication of a coming revolution in art jewelry is credible because of the development of new tools capable of creating a similar climate of access in the design, manufacturing and distribution of objects. The imminent broad access to these tools will indeed warrant the title of Art Jewelry 2.0.

In 2006, Google bought and began distributing an open source 3D modeling software program called SketchUp. Today anyone can download this freeware program and in minutes be creating credible digital renderings. The highly intuitive interface of SketchUp lowers the threshold of technical expertise and in many ways mirrors the accessibility granted by Web 2.0 platforms that separated form from content. SketchUp is the first widely distributed, freely available CAD program with the potential to broaden access to digital design. The implications are vast. Imagine the everyday computer user empowered to start using 3D modeling software to design their own buildings or objects the same way they now share text, images and video. A 13-year-old in Sri Lanka can design award-winning desks for IKEA after he finishes his homework, or a surgeon could design specialty tools to enable new procedures.

If most object users are also object designers, even at an amateur level, then the ability to participate in the design process will almost certainly be parlayed into the mass-customization of manufactured goods. This trend is already well underway, though with somewhat limited design tools. Nike’s ID project – where customers can design their own sneakers online – and jewelry manufacturer Stuller’s program CounterSketch – which allows customers to design, customize and price their own jewelry – are but two examples of many. As user interfaces and software become more affordable, accessible and easier to use the impact of DIY design will be comprehensive.

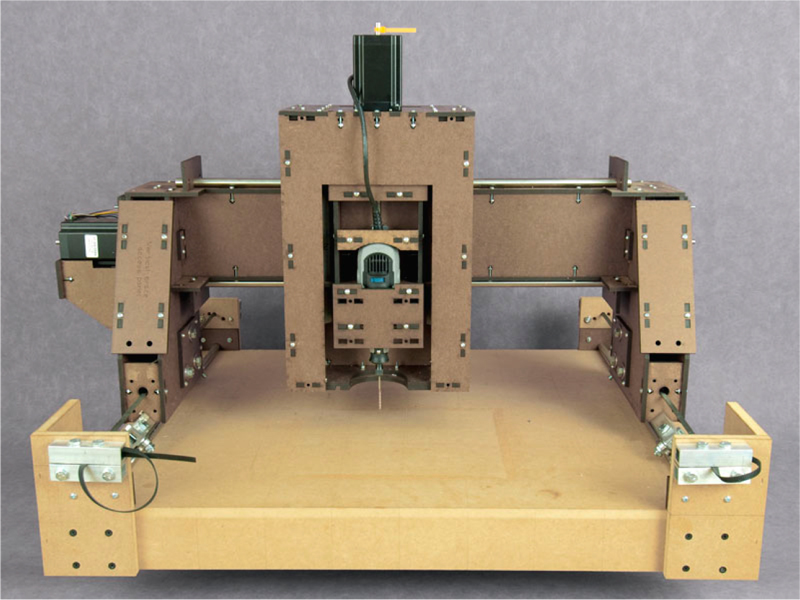

Two methods to mollify the exorbitant expense of computer-aided manufacturing have emerged recently. The first is the open source sharing of plans to create rapid prototyping and computer numeric controlled (CNC) milling machines. A number of public and private entities have collaborated to make these designs widely accessible and easy to build. One example is the open source DIYLILCNC project developed by Taylor Hokanson and Chris Reilly based on plans from instructables.com. Using these freely available plans and open source Linux printer driver software, anyone can build a CNC router for around $700. Further, the DIYLILCNC can be used to manufacture parts to create a duplicate, making it a self-replicating machine. This is a dramatic leap in accessibility (though not necessarily quality) from previous models that cost in upwards of $10,000. As print quality improves and cost comes down, access to computer-aided home-manufacturing becomes plausible. In the next decade an all-in-one home CAM printer for around $500 is a real possibility, even with current technologies.

The second method of creating access to computer-aided manufacturing is the fabrication laboratory or fab lab. A typical fab lab is a well-equipped machine shop outfitted with numerous digitally enabled manufacturing tools. There are a number of fab labs around the world that allow private use of their machines for a nominal fee. In just the past few years a variation on the fab lab has developed, the on-demand or online fab lab, of which ponoko.com is one such example. With Ponoko a user can digitally design an object and send the file to be printed. The object is then printed and sent back to the user, offered for sale to the public in an on-demand printing scheme, or made freely available to other users at the designer’s request. At first glance Ponoko seems like a gimmicky website that provides an online community-centric manufacturing business model similar to many others. However, Ponoko has the ability to manufacture and sell anything that a user might want to upload or even download, making them more like the ‘long tail’ of amazon.com than other niche-product websites.

The real revolution will begin as all of these tools for design, manufacturing and distribution are combined. And for this we must depart from what is currently possible, though it is not hard to imagine what kind of manufacturing revolution we are in for. As online fab labs abound, the average computer user will be able to design (in SketchUp) and upload a file of a table, a bracelet, or a doghouse and have it built and shipped in days. In the vast inventory, short wait ecommerce environment of Amazon and Netflix the ability to easily design and build objects will result in the ultimate customization experience. Further, the ability to differentiate oneself as an individual – often through unique personalized objects – and the sense of belonging afforded by participating in a (digital) community are two methods by which people derive identity. The DIY digital design/ on demand manufacturing paradigm satisfies both of these impulses.

Also of great significance is the emergence of the home CAM printer. The recent proliferation of a variety of digital media through online distribution has deeply affected how books, music and movies are sold. With home CAM printing, digital files of objects can be sold, downloaded and printed in the same way you might buy a mp3 or eBook. Think of the affordable home CAM printer as the next iPod, Kindle, Nook, or iPad; a device capable of delivering digital content for dynamic personal consumption. The sales and distribution mechanisms are already in place through amazon.com and the iTunes/ App/ iBook stores. Moreover, an object file could be downloaded, taken into a computer aided design program, modified, and then either printed as a modified object or re-uploaded as a new variation of the original object for purchase, thereby creating an active and participatory climate for object design and manufacture. Quite obviously the barriers to access are falling and producerism is our new reality.

The implications of broad access to computer-aided design, computer-aided manufacturing and digital distribution is astounding. On demand manufacturing, where the consumer/producer wouldn’t have to leave home to obtain their product will revolutionize global manufacturing. Think about the reliance of the West on cheap manufactured goods made in Asia. Home CAM printing has the ability to dramatically decrease the need for imported products. Big box distributors who profit most from the mark up of cheaply manufactured goods will be effectively marginalized. The whole global manufacturing complex will be thrown into upheaval, with consequences too far reaching to imagine.

Perhaps, home CAM printing will also be environmentally superior to traditional manufacturing. There will be special CAM printer compounds and cartridges to give the objects created by them the ability to be put into infinitely recyclable material streams, a design scheme known as cradle-to-cradle.

Undoubtedly though we will see the same problems in object manufacturing that exist in digital media today. Once you have a file for an ergonomic pair of scissors, a toothbrush, or a brooch you can print one, five, or even 300. Once everyone can design and manufacture their own products one major issue left unresolved is how copyright on home manufactured goods will be enforced? Will Walmart just sit and watch their business model evaporate, or will they fight like the media publishing industry to ensure their profits? Will low-cost distribution outlets wage a war against illegal product manufacture and enforce digital-rights management over objects? Unless we re-examine our current intellectual-property laws the future might see police stopping citizens on the street asking to see certificates of authentic manufacture.

The entire notion of technology 2.0 is about access, hopefully something that is exceedingly clear and plausible given the examples here. Access to digital media is commonplace and universal access to design and manufacturing is nearly here. The question remains, how will this affect art jewelry? Just as CAD and CAM technologies forced us to reevaluate our definition of art jewelry in the 1980s and 1990s, so too will the revolution in access cause a broadening of the scope of art jewelry. No longer an absolute condition of the studio, of limited production, or the use of metal, art jewelry today is characterized by the intention of the maker that brings it into existence. An undeniable segregation exists today between those who make, those who collect, and those who exhibit art jewelry. Art Jewelry 2.0 promises to erode those distinctions by granting access to anyone to become a producer/consumer, maker/collector, or designer/retailer of art jewelry.